Test & Validation

Tests can be divided into a few group:

-

Hardware, Software and System:

- Functional tests to prove the concept and confirm required functionality,

- Validation tests to prove standards regulations

Any requirements and assumptions: safety, performance, reliability, environmental must be verified to check the compliance. We can perform validation and finalize it by report.

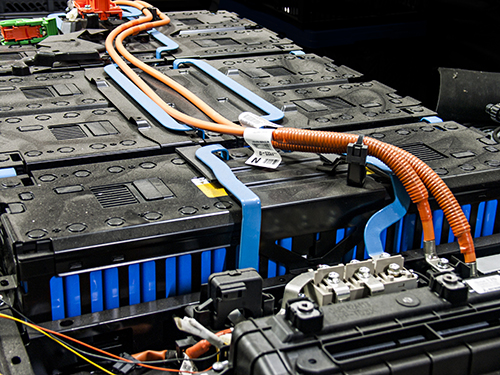

High Voltage

Apart of common electronics, we specialized and cooperate with experts in service and testing:

- Batteries pack,

- Energy storage,

- HV DC Circuits,

- Electric Vehicles

Test & Validation - portfolio examples

Test specification

-

Building the specification:

- Functional specifications

- Safety requirements

- EMC test plan

- Detailed test plan

Specification is an initial stage of each engineering project. It contains of legal, functional or reliability requirements. Depends on Customer it can be one page description as well as hundreds of pages.

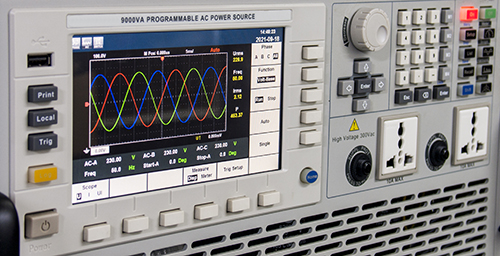

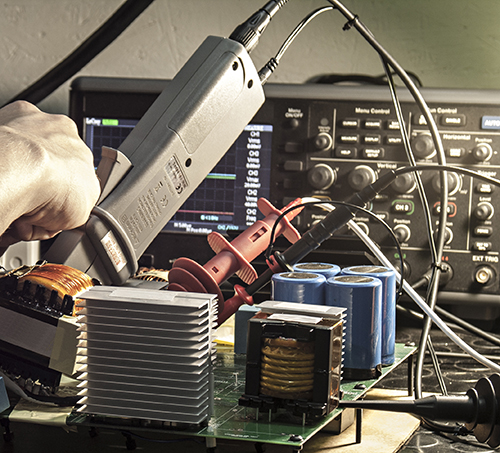

HW Testing

- Functional verification

- Safety analysis

- Construction overview

- EMC Pre-compliance

- Troubleshooting

Testing hardware must be planned based on Customer's expectations or standards. Any procedure should follow the assumed scenario and should be perform with attention to details.

Risk analysis

- Description of technical project risks,

- DFMEA,

- Risk assessment based on calculations, simulations, analysis,

- Proposals to reduce the risks

- Worst case analysis

When new project or component changes are consider, any of them may involve risks. To avoid critical issues at certain milestones huge effort is taken.

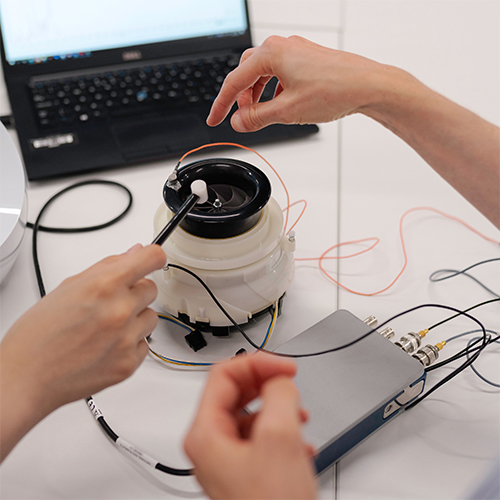

Bring up and troubleshooting

Considering any development project, bring up or commissioning are huge steps. Besides design procedures confirmed by theoretical analyzes and even simulations, they are the most obvious way to confirm product functionality. During these phases research prototypes become more mature and circuits can be reused in development process.

Usually, previously proven concepts should be adapted to development project, what can cause problems that need to be solved.

At these stages we solve as many issues as possible.

Thermal measurement

For power elecronics thrmal aspects are especially important. High temperature can reduce the lifetime and affect the reliability and safety. In our proctive is very common to verify calculations and simulations by specialized equpment like thermal camera or dedicated sensors.

Power Quality

TES is able to perform power quality tasks with specialized equipment. Cooperating with our partners and their laboratories we can provide reliable results for any almost applications. Our analyzers split the signals up to 50th harmonic.